Example

Results 21 to 30 of 95

-

06-02-2013, 03:20 AM #21

Featured Sponsor

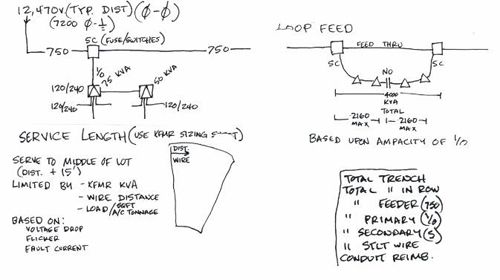

Featured SponsorThis is what I've gleened so far for our system...typical 12,470/7200

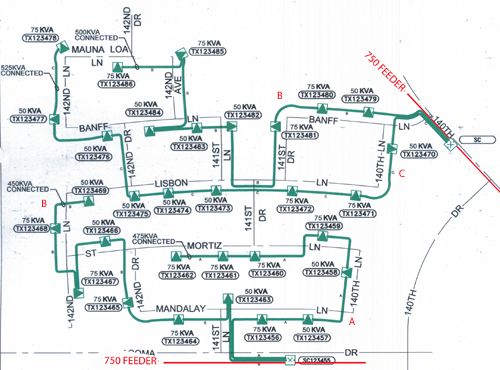

And a typical "example" 750 Feeder (from the dip) to a switch cabinet, then the 750 runs between Cabinets and the primary 1/0 makes the radials and loops of the transformers.

-

06-02-2013, 03:23 AM #22

-

06-02-2013, 11:59 AM #23

I'm still getting a feel for the system, and the various configurations.

It's pretty clean with pretty much all 750 feeder and 1/0 primary.

-

06-02-2013, 02:52 PM #24

Junior Member

Junior Member

- Join Date

- Jun 2013

- Posts

- 5

loops

loops

I don't see the problem with a different circuit as long as it is the same phase. One thing that always bugged me going out on URD was opening up all the transformers and never having a stand off bushing in them. Yeah I know you should carry some and we did but it got old fast having to put new ones in every time we opened one up.

-

06-02-2013, 03:55 PM #25

Umm I agree wif ya ever tranny shud be equipped with standoffs or parkin stands or whatever ya call em.

-

06-02-2013, 04:09 PM #26

Senior Member

Senior Member

- Join Date

- Feb 2007

- Location

- Ontario Canada

- Posts

- 1,284

Really a parking stand at every transformer? How many transformers do you think you have? Every time you close to move an open point you gain one, I think you just have to know how many you need when you leave and stock accordingly.

-

06-02-2013, 08:51 PM #27

Our system looks to be about the same. All our feeders are 750 from the dips and between switch cabinets, then all the UG primary is 1/0 (looped to another cabinet if possible). Everything (Feeder, Primary, and Service is in it's own conduit). I don't think we ever direct bury anything (except maybe temp service). Looks like 5"C is typical for the 750,and 2"C for the 1/0 Primary. Looks like a pretty clean system (example from our design manual).

I'm digging through the spec/mat'l manuals and learning the "rules"...

Most transformers are Dead Front, but I know there's still some old live fronts out there. The labels seem well done also, as they are the stamped-raised metal tab type, so even if the color fades (black on yellow) it looks like you'll still be able to read the raised numbers. And they get attached to the end of every cable run/termination point from what I can tell. It looks like we have a pretty clean system. Dam, I can't wait to get started, just listening to you folks! Nice to be involved with a job/product here again that's one of the few things still proudly "Made in the USA!" And, what a GREAT forum here. I appreciate every post!

Last edited by URDesignerCub; 06-04-2013 at 11:20 AM.

-

06-03-2013, 04:08 PM #28

We used to have tons of livefronts used as switching pots...stayed that way for years.Ill assume that thats unusual today.

-

06-03-2013, 07:05 PM #29

Senior Member

Senior Member

- Join Date

- Dec 2012

- Posts

- 99

We still have a handful of those... They are probably the worst thing you could run into when you get an urd fault. Especially annoying when there are no labels, no fault indicators and your company doesn't let you lift live fronts that are dead with any load connected and you only have one other guy to help. I've had a few of those that took roughly 16 hours to find the faulted section... live front switching stations are by far the worst.

-

06-03-2013, 07:46 PM #30

Our Typical...

Featured Sponsorr

Our Typical...

Featured SponsorrSystem example from the design manual...

Reply With Quote

Reply With Quote